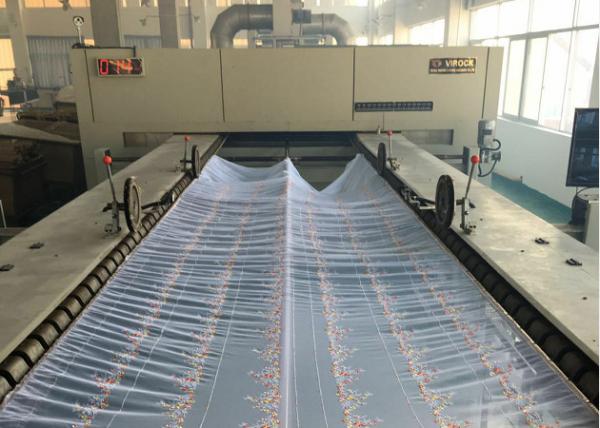

Low tension Stenter Finishing Machine , open - width entry , energy

conservation

1. Function of stenter Machine

1) Heat setting is done by the stenter for lycra fabric , synthetic

and blended fabric.

2) Width of the fabric is controlled by the stenter.

3) Finishing chemical apply on fabric by the stenter.

4) Loop of the knit fabric is controlled.

5) Moisture of the fabric is controlled by the stenter.

6) Spirility controlled by the stenter.

7) GSM of the fabric is controlled by stenter.

8) Fabric is dried by the stentering processs

9) Shrinkage property of the fabric is controlled.

10) Curing treatment for resin, water repellent fabric is done by

the stenter.

2. Machine Process:

Open width entry --- Infrared center guider---- Finishing Padder

---- Various tension applicator ---- Infrared center guider --- -

Lower Overfeeding device ---- Upper overfeeding --- Edge detecting

& uncurler device ---- Pin-on ---- Inlet steaming & edge gumming

----- Chambers for heat setting ----- Pin-off ---- End section ----

Edge cutting & suction ---- Air cooling ---- Plaiting.

3.Technical specifications:

● Roller width: 1600-3800mm

● Working width: 1400-3600mm

● Heat source: Gas/oil/steam/electricity

● Chambers: 2-12

● Width adjustment range: 500-3600mm

● Machine speed: 10~150m/min

● Temperature of chamber: 100-220℃

● Fabric held by: Pin/clip/combined

● Air pressure: above 0.5mpa

● Infeed upper overfeed range: -10% to 80%

● Infeed lower overfeed range: -10% to 80%

● Exit overfeed: -10% to 80%

● PLC & contactor: Mitsubishi/optioal

● Frequency converter: Mitsubishi/optional

4. Components of Stenter Machine:

- Entry frame

- Padder with tension applicator

- Weft straightner (Mahlo)

- Entry rail

- Heat recovery

- Attraction rollers

- Circulating fans

- Exhaust fans

- Cooling zone

- Winder

- Clips

- Pins

- Plaiter/Batcher